Hi @chriswmackey , apologies for the radio silence here, and happy late new year to you too! I have found some time to look at this again and I was able to successfully integrate the night time ventilation into my current grasshopper script, so thank you very much for this!

We are using Rhino 8 now so I have re installed pollination for Rhino 8, so far so good.

Our next step of development which could be fairly complex is the inclusion of MVHR in the model. For residential Passivhaus dwellings with MVHR units, we need to be able to include this in the TM59 modelling, how do you recommend we go about doing this? Ironbug seems like the most appropriate, but potentialy more complex solution, do you have any experience with this, as I couldnt find much guidance on the LBT forum.

For reference this is the type of unit we would look to model: Compact P - Nilan | England & Wales Distributor

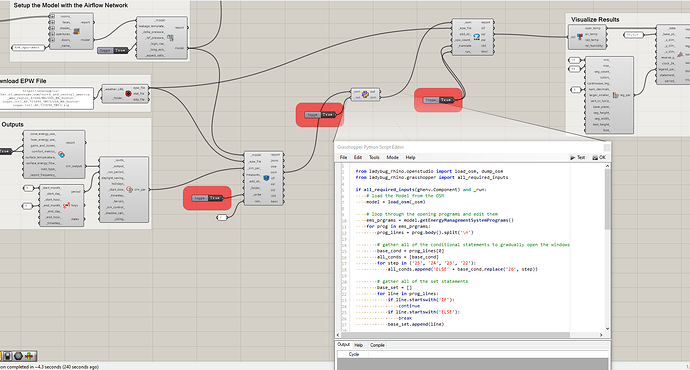

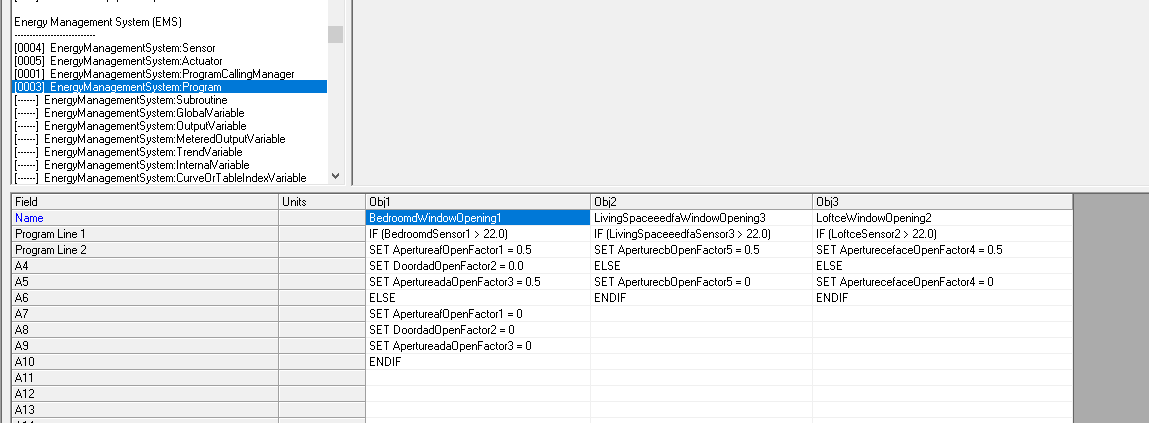

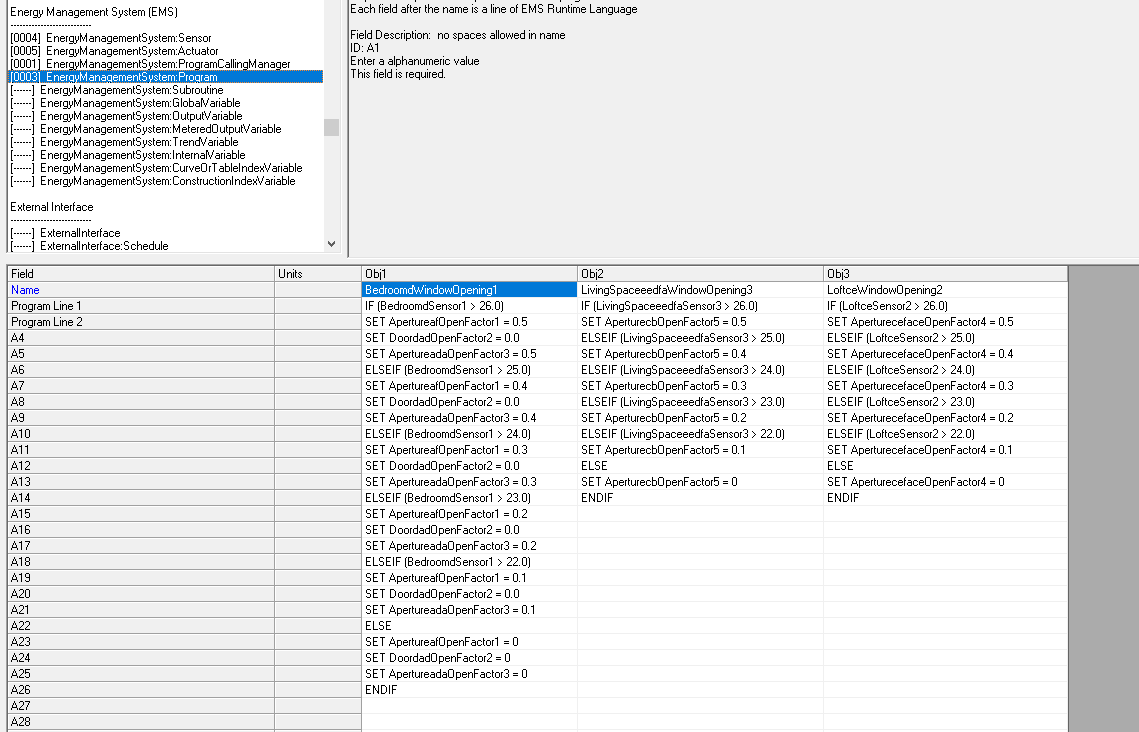

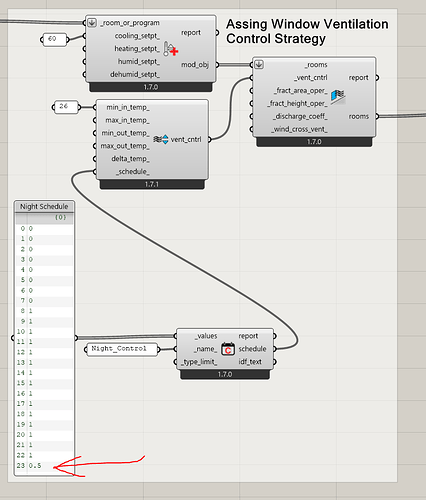

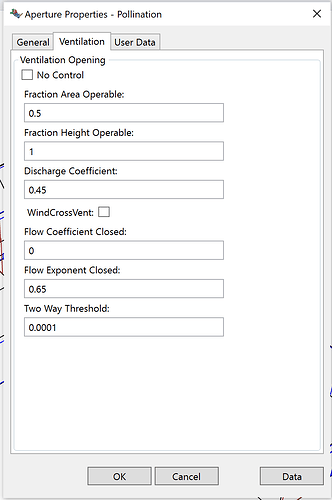

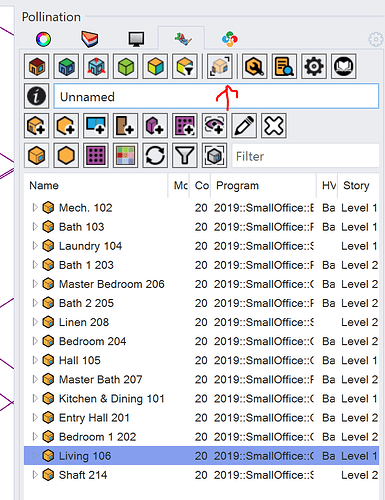

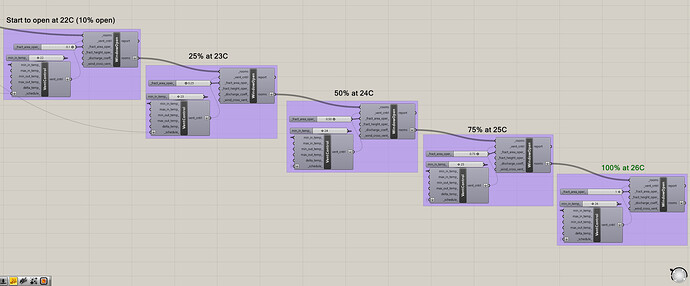

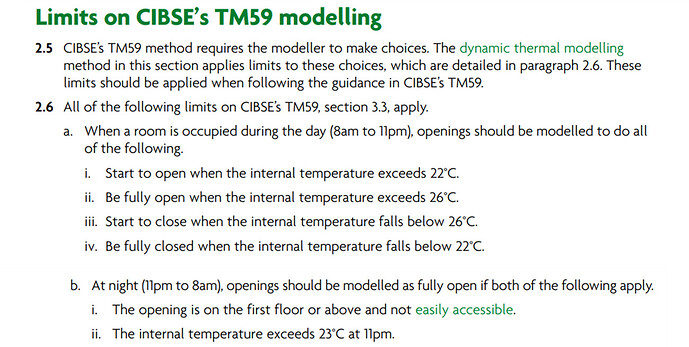

I have also attached our latest grasshopper TM59 script, if you have any time it would be great to get some feedback on the approach we have arrived at. One thing that I have noticed to be potentially a little awkward is appling different opening areas to different windows/rooms easily in Pollination-rhino. In vanilla honeybee-grasshopper this would be fairly straight forwards by referencing surfaces, grouping in grasshopper and applying free area that way, but I couldnt find a straight forwards way of doing this in Rhino Pollination… any thoughts?

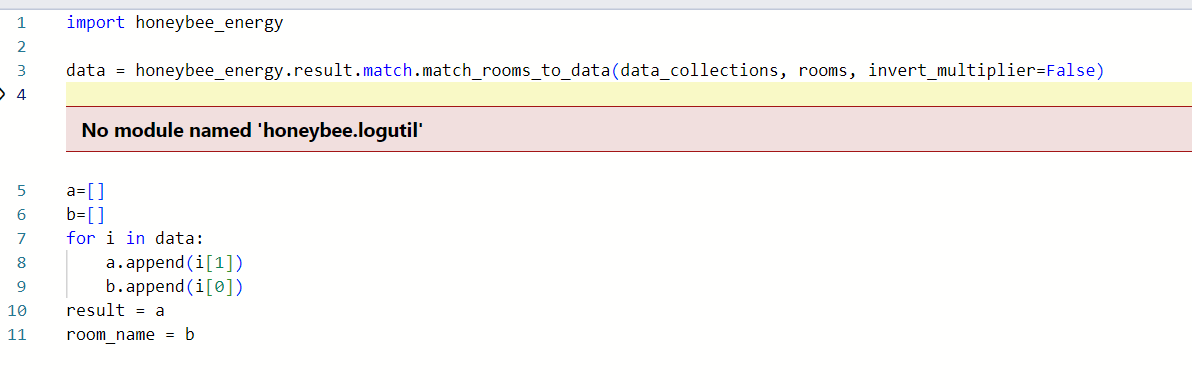

One final comment, after the upgrade from Rhino 7 to 8, some of my python components have the ‘old’ tag, I have been able to migrate most of these except this one which contains the following code:

import honeybee_energy

data = honeybee_energy.result.match.match_rooms_to_data(data_collections, rooms, invert_multiplier=False)

a=

b=

for i in data:

a.append(i[1])

b.append(i[0])

result = a

room_name = b

when I transfer over to python3 component I get the following error shown in the screenshot below. Any ideas as to why this is the case, and how I could fix this?

231107 TM59 Workflow_Pollination_MG_V4.gh (411.8 KB)